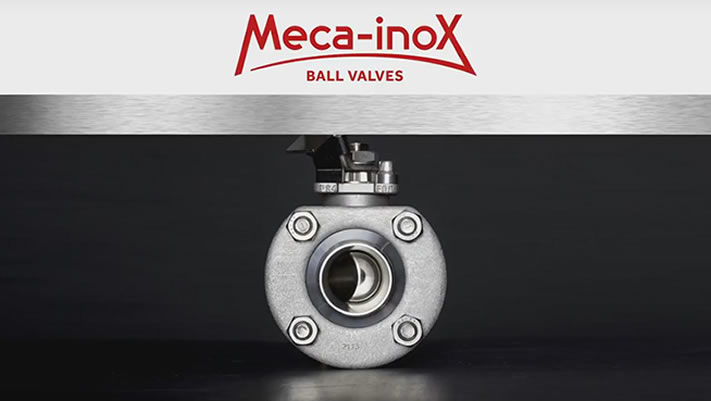

A product durability recognized for more than 60 years and a quality of production and assembly of the first rank are the major features of MECA-INOX that is now offering a product warranty of 3 years. This new warranty is an important step in the company customer’s satisfaction strategic plan “PREMIUM 2020 MECA-INOX” and confirms the band as a reference in ball valve market in Europe.